Trumpet Spit Valve Maintenance

So, maybe you’re here because you have a spit valve issue with your Trumpet. You might be the smart kid who just doesn’t ever want to have a spit valve issue. There are no guarantees, but let’s look at some things. If you’re just interested you might want to start at the more general spit valve post.

Most of us have regular lever style spit valves with cork stoppers that work great – until they don’t. Some of us have Amado “water keys” or knock-offs in that push-button style. Let’s look at both. (Skip down to here for Amado-specific info.)

The standard lever and cork style spit valve has been around a long time. There are few problems with them if you take good general care of your instrument. I have a good friend who made his living selling appliances who once warned me that “everything breaks”. He’s right. What breaks on our spit valves can include:

- the cork disintegrates or falls off

- the spring breaks or fails

- the solder fails

- the screw backs out

- something gets bent out of shape

Let’s look at each cause and some solutions.

If your cork looks like this, it’s time for a new one.

I hate to admit it but that’s the C Trumpet I use all the time. It was new in 1979 and I know for a fact that you’re looking at the original cork. Yuck. I need to get a new one on there. When I do, I could just scrape out that crusty specimen and glue in a new one with a little dab of glue-gun glue. I probably won’t, though. I’ll take it to the shop and ask for a new replacement spring at the same time. Why wouldn’t I replace the spring myself? Read on …

The cork (or rubber, or silicone, or goatskin pad) is glued in place and can fall out. If yours did that and you managed to find it intact, or to not lose it you can just glue it back it with a little glue-gun glue. Don’t remove the whole lever business or you might have a tough time getting it all back together (see below). If you did lose the cork, it’s quite possible that it’s in your case or that your band teacher has a spare in their repair kit. If not you’ll need to visit a repair shop or try your luck ordering it off the internet. These things come in a variety of sizes, so you’ll need to do some careful measuring or get a variety pack. Real repair technicians used hide glue in the old days but I think most of them just keep a glue gun hot for this kind of thing nowadays. They use those glues because they can undo them with a little heat. That’s an important feature – like the undo feature in computer software! DON’T USE CA (aka SUPER or KRAZY) GLUE! Some synthetic replacement “corks” have their own sticky backing – trust it if you dare. There are black rubbery ones with a nipple that goes right in the hole to reduce turbulence! If you have an unusual Trumpet from Europe your “cork” might actually be a very delicate goatskin pad. I have one like that and when that thing gets ratty or torn it’s probably going to be replaced with a nice new cork. If you really want a soft pad on there any repair shop that also handles woodwind instruments will have one.

If your “cork” is actually rubber and has a little nipple-like thingy that extends right up into the hole you’ll have to make sure that it is all lined up before you glue it in. I noticed recently that the rubber had hardened on my Yamaha Flügelhorn’s spit valves – I could hear them “clacking” shut. Naturally I poked one with my fingernail and it fell right out. Where I practice isn’t exactly tidy, but I did find it and glueing it back in wasn’t as easy as described above. I put the nipple bit into the opening and closed the valve, moving things around until it fit at both ends. Next I held it in the hole with one hand, put glue in the right spot with the other and closed it firmly. That should have been all it needed but the glue cooled and dried too quickly and it wasn’t seated as well as it should have been. I wanted to fix it so I went to remove it and it just fell out. Oops. Next time I heated up the cup first so that the glue would have a chance to flow before it cooled and that did the job. I used a candle because that horn is silver plated (so it wouldn’t melt any lacquer) and I’ve learned the hard way not to use a torch if I don’t have to. The dab of glue went into the hot cup, not onto the rubber this time and all is good. I guess if those rubber stoppers are going to harden up I should plan to replace them occasionally. Hmmm. Here’s a few photos of that operation:

If the spring on your spit valve breaks you’ll likely have to come up with a DIY temporary solution and then take it to a real instrument repair technician to get a new one. My friend Audrey was playing with a major symphony orchestra when this happened to her. The guy beside her was gob-smacked by what happened next (doesn’t that sound like YouTube click-bait?) She reached back and pulled out her pony-tail – unleashing an explosion of curly locks – then used the hair tie to replace the spring. She claims that she didn’t miss a note. The spring broke while she was emptying her spit in a rest and she had the solution in place before her next entrance! Since she told me that story I’ve made sure there’s always an elastic in my “stuff”. If you don’t want to carry an elastic just make sure you’re friends with someone that wears a pony tail – a great way to meet that special someone! Try it just for fun -the elastic spring replacement, not the pony tail – please. It only takes about 5 seconds once you’ve figured it out.

In the time between typing that story and getting this page posted I had a similar incident. I was in the pit playing an opera and just before it started I did the usual spit dump and felt an unusual “click”. That was one side of my C Trumpet’s spit valve spring breaking (the one in the photo above). It has 2 springy sides so I thought about just leaving it but Audrey’s tale was fresh in my mind. I never did get around to replacing that disgusting cork (in the photo above) but at least I took my own advice and threw a spare rubber band in my Trumpet case. It took less than ten seconds to install it and I was back in business, feeling confident! I had time to spare so I snapped this photo. If Angus MacGuyver played Trumpet, it would look a bit like this:

Next trip to the big city and I’ll get a nice new spring – not the cheapo one in that other photo (below). I want one that’s going to last me another 45 years!

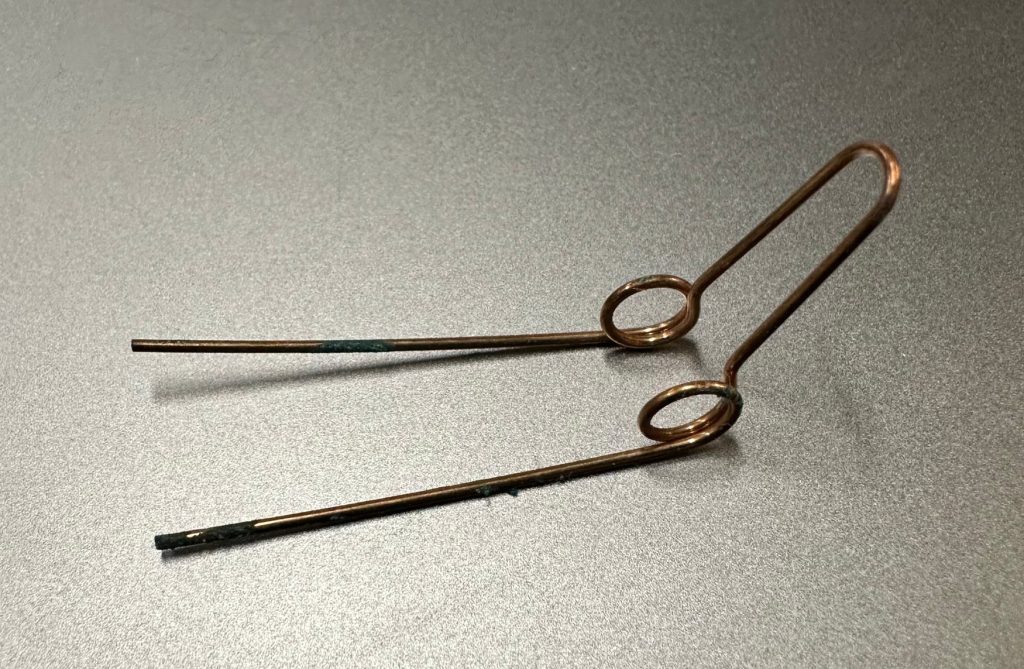

Staying on the spring business, there’s a reason I don’t replace my own springs. Ok, maybe 2 reasons. The first is that I don’t want any old spring on there, I want the best spring I can get. The second reason is that those repair techs cheat! Yup, they have special tools for some of these springs. When they don’t cheat, they have springs that look totally wrong until they use their ridiculous length, get them in place and then clip them down to size. This is why you might think twice about taking that lever off your Trumpet to clean the leftovers out of the cup where the cork goes. The spring below looks way too long. Those long legs make it possible to get the spring in place, then they get cut off short. (Without them it can be really difficult – which is why I suggest leaving that lever in place.)The first time I tried this I left a tool mark on a Trumpet – just sayin’.

Solder is like metal glue – that’s glue made of metal. It goes on molten and hardens to attach two hot pieces of clean metal and that’s how almost everything on our Trumpets is attached. If the solder fails and your spit valve falls off you really should take it to a good instrument repair technician. I consider myself pretty good with electrical soldering but I almost never do a tidy job on an instrument. I can attach something in an emergency but it won’t be pretty. If you haven’t done it much and you like how your instrument looks and works, get a professional to do it. If you think you can do it you should probably know that your Trumpet is put together with a variety of solders that melt at a variety of temperatures. It’s easy to heat up one thing and have something else come apart – that’s experience talking.

A fairly common issue is when the screw that acts as the pivot point on your spit valve simply comes partially (or completely) undone. If it comes completely off you might be unable to get it (especially its spring) back into its place in a way that works for the spring. That might need a visit to a shop and a new spring. You want to avoid that if you discover that the screw has just come undone at the end with the threads on it. That’s the most common condition. Normally we discover this when our Trumpet sounds really bad – almost like a kazoo. You want to use a thumb to position the threaded screw against the threaded hole on the little brace that holds it, then turn the screw clockwise until it’s snug. Don’t crank on it with a tool or you risk snapping it and you’re off to the repair shop. If you crank on it hard enough you might bend that brace to the extent that the whole pivot action can’t happen; which brings us to the next point.

If somehow your spit valve got bent out of shape – slow down! First, make sure that it is actually bent. It might be that the screw is partially backed out (see above). If the end that covers the hole is doing its job you should probably leave it alone even if it looks funny. A bold repair tech, or a helpful band teacher or parent would probably just try to bend it straight and hope it doesn’t snap in half. The difference is that the repair tech can either solder it back together or grab a new one off the shelf. If it’s bent and it works, it isn’t broken. (Read: “If it ain’t broke, don’t fix it”.) If you’ve ever bent a wire coat hanger back and forth to break it you know what I mean. Brass is a lot softer.

And finally … the Amado (or Amado style) spit valve is a pretty slick invention until something goes wrong. There could be other issues but these are the ones I’ve run into:

- the valve gets stuck open or closed

- the entire thing falls or breaks off

- the internal spring breaks or fails

- the retaining ring mysteriously falls out and bits are missing

Let’s tackle these issues:

If the Amado spit valve gets stuck or sticky it might just want a drop of your valve oil (which might have prevented this problem, but hindsight is 20-20). If it starts to work better and better, you’re in business. If it isn’t interested in moving at all this could take a while. You need to push on the plunger that’s inside. If the end that you would normally push on seems pushed in already then your valve is stuck open. If that plunger seems like it’s all the way out and won’t move your valve is stuck closed. My response to either condition does not involve a hammer. If your Amado water key is stuck open, you can’t play, so let’s look at that first. You’ve got some oil in there, so let’s push that plunger back out the way it came in. You need something tiny and strong like the mighty paper clip – my personal favourite. I look for the bigger ones – strong, but not too big to go easily through the little vent hole in the back. Often this will be enough to get the plunger moving. Use the clip and your spare thumb to work the plunger back and forth until it cooperates. If it never really wants to move on its own (by the strength of its spring) you probably have a broken spring inside the valve. I’ve suffered that fate on the old Getzen 4-valve Flügelhorn (above) that I should never have parted with. Alas. See below for that broken spring. Keep reading if you can’t move that plunger.

Below are some photos of my old Bach Bb while I was solving the stuck open condition which was just one push after it being stuck closed. Hmm.

If, on the other hand, your Amado spit valve is stuck closed you do at least have the option of playing the horn and dumping the spit by pulling the slide like the old days (in which I still live with some Trumpets). In the event above I did what most folks would do … I oiled it and got it to open. Then it was stuck open but not so stuck that I couldn’t get it moving. If you’ve already broken a bunch of things in your mechanical adventures you probably know that feeling you get just before you apply too much pressure and something breaks. If you’ve haven’t yet broken a lot of things let’s not start with your Trumpet, so don’t push too hard on that plunger button.

Having tried “reasonable force” and got no movement I would remove the slide that it’s on and hit that split valve with some penetrating oil. Depending on what you’re using that stuff can be smelly and/or damaging to your Trumpet’s pretty finish so don’t go crazy with it. Shoot a little down the slide to get it working from the inside and then drop a little into the key through its vent hole. Do that step with something like a toothpick, your paperclip or the detached straw from a spray can. You can spray a little in the can’s lid and dip in it. Give the stuff a few minutes to do its job then try moving the plunger again. Worst-case-Ontario you might want the penetrating oil to work overnight. That rarely fails. If it does fail it’s probably time to repeat the process then head off to the repair shop. If you’re successful and everything is great STOP! Remember all of that nasty gunk (not a brand endorsement unless someone at GUNK™ would like to send me some product) you sprayed in there that probably smells bad and might damage your finish? Yup, you’ll want to wash that stuff out really well. It might take several soapy washings and rinses inside and out. Lube the slides and you’re done. That was easy.

It’s unusual but occasionally an Amado water key will come right off the horn and leave you in a lurch. It is possible that this happened because the original solder wasn’t done right (a whole other subject) but more often than not they come off because of some sort of unplanned trauma. If you read my warning above about how much force is too much force, then you can guess one of the ways it might have come off. It could have been whacked hard against a music stand, or a chair or because it doesn’t fit in the case properly. Regardless of how it came off I strongly recommend that you take it (if you can find it) with your Trumpet to a proper instrument repair shop and have a technician you trust solder it on. There are too many ways to mess this one up by trying your luck.

Occasionally the little spring inside an Amado water key will fail. That generally looks like it simply got tired and broke in half. You can buy these on the internet but if you have a local repair shop I’d try there first because they probably have the good ones, not the really cheap ones that’ll put you right back in the same spot next year. Their technician might just pop it in there for you while you shop for some cool stuff – a win-win! If you’re brave and/or just can’t help yourself you’re going to have to pop the little clip off the back of the thing being extra careful not to lose it, or the washer, or the spring or the plunger. I like to use a little spring clip tool but you can get it out of its groove with all kinds of things. There are some good videos online already of folks accomplishing this. Here’s one. Replace your broken spring with a nice new one and put it all back together. Getting the clip back in can take a long time if you have to go looking for it, so keep a thumb on it while you fiddle with it. Oh yeah – one more thing. When you think you have it back together it’s time to make sure that the spring clip is in its groove. It might just be sitting against the sides of the tube waiting for you or the spring to apply enough pressure to send the bits out of their happy place and into orbit somewhere, which can lead to the final failure condition…

If you find that the retaining ring/clip has mysteriously fallen out and some of your Amado Water Key’s bits are missing you’re going to need new ones, or a really good search party. Nothing is really going to substitute for the real thing, so get some genuine Amado parts online or at a local shop. The local shop is your best bet because you can make sure that they fit before you leave. There are some cheap overseas knock-offs that may or may not have interchangeable parts. Some of them are scary looking. Just sayin’. If, by chance, you have a knock-off Amado-style spit valve your repair shop can easily remove it and replace the whole thing with a real one. That’s what I’d do.

Having opened up that can I guess we should address those knock-offs. The really cheap ones cost a lot less because they are not made anywhere near as carefully. The ones you can find on the inner-tube for $15/dozen are garbage.

Having said that, there is a real music equipment company that uses and sells an improved Amado-style water key and that’s a whole other thing. Take a look at the Harrelson site and you just might want one – I do! Rumour has it that they also make great Trumpets. I haven’t played one yet and I’m kind of afraid to … it’s possible that I have too many Trumpets. Shhh. Please don’t tell my wife.

There’s a newish thing called Orbit that looks space age and seems to be well-made. My friend Vince Mai had them put on his workhorse “FrankenTrumpet”* and he loves them. He’s been around a long time and uses his horns hard, so I trust him. They had those Orbits at Harrelson Trumpets too. Your repair shop could solder one on lickety-split. They look like this (in low light):

- *Vincent Mai is a very successful Vancouver-based Trumpet and Flügelhorn player who had a friend (whose name will eventually come back to me)in Toronto – home of the amazing Blue Jays, the mighty Raptors and also of the lowly Maple Leafs – build him the custom Trumpet above. “It does everything I want it to!” – This from one of those Trumpet players who seems to be able to make a Trumpet do anything.

Somehow I got off track. We’ve covered the most common issues with spit valves, at least the ones I’ve dealt with. I’ll ask around about other ones. If you have a really unique problem you should probably take the Trumpet to a repair professional, or leave it by my back door and I’ll take a look at it!

Leave a Reply