So, how do trumpet valves work? Let’s look at the mechanism that made the Trumpet able to play all of the notes encompassed in the player’s range. This also applies to valves on tuba, euphonium, a variety of Drum Corps instruments and so on. (The general principles also apply to rotary valves on French horns, trombone triggers, some tubas, German Trumpets and some other things. The difference is that in those instruments the valves rotate instead of going up and down. If you ever get a chance to drive an old Mazda RX-7 or RX-8 with its Wankel rotary engine you’ll know that pistons aren’t better, just different. We’re talking here about Piston Valves that typically go up and down.)

Why Do Trumpets Need Valves?

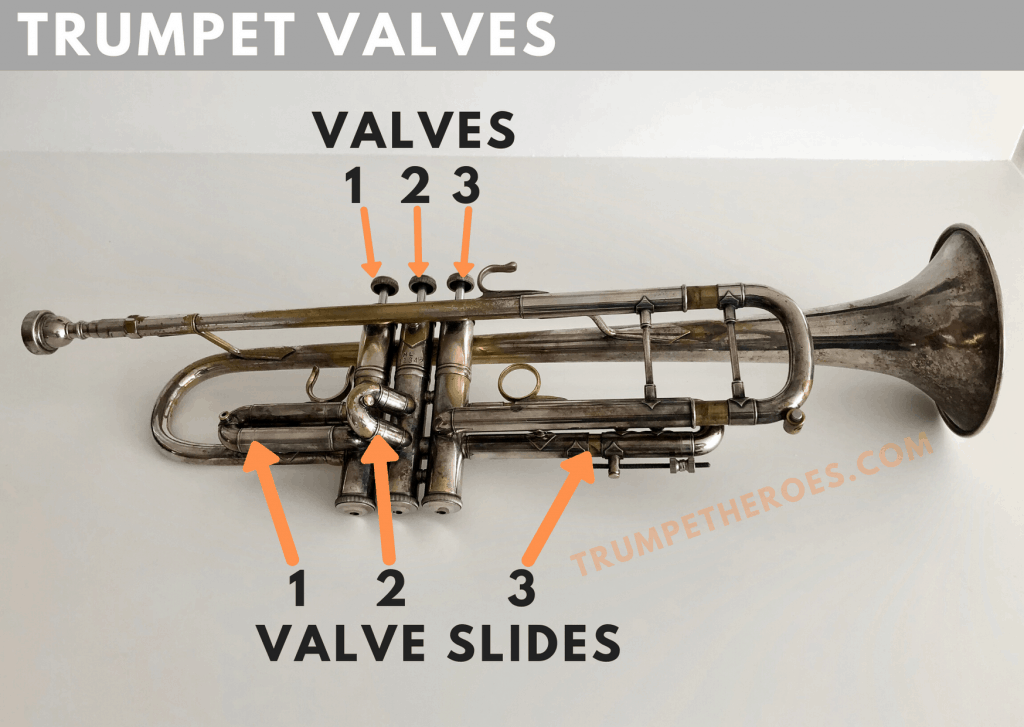

Before valves, players of these instruments had a very restricted group of notes available to them. That group of notes is called “The Harmonic Series” and a good explanation of that phenomenon would take a while. It was only capable of playing the notes that we’ve all heard in Bugle calls. To play other notes required a different length Trumpet and another and another. A regular Bb Trumpet is a tube that is 1.475 meters long (almost 5 feet) if you unravel it. The second valve, when pressed, redirects the air column through another .09 meters (9cm or about 3.5 inches). That’s enough tube to lower the pitch of that Trumpet by one semitone. In effect, you now have a Bugle in A. The first valve’s tube is twice as long, about 18cm or 7 inches. That drops the pitch a whole tone into Ab. The third valve is about 28cm, so about the same as the first two put together and so on as you add to that length by pressing multiple valves. (The lengths get progressively longer because when using more than one valve you’re adding length to a longer instrument.) Anyway, the result is that the modern Trumpet player has access to seven different lengths of Trumpet that share a bell and mouthpiece. That’s enough different lengths to give us access to all of the sharps, flats and natural notes within our range. The rings on the first and third valve slides enable the player to further fine tune notes downward. Some notes really need it.

Trumpet Valve Basics

Valves make Trumpets longer. If the purpose of a valve is to make a Trumpet longer (or not) then it has only two positions: up and down. Pushing a valve down makes the instrument longer by the amount of tubing attached to it.

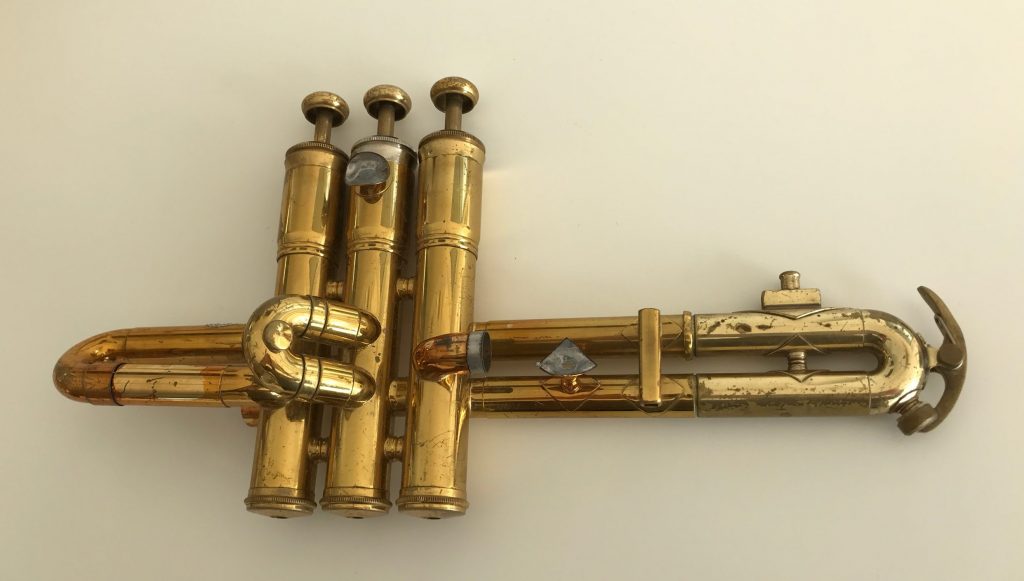

Each valve has a simple tab and groove setup that should make sure that the valve can only go straight up and down. In some Trumpets the spring that pushes the valve back up is floating around free under the valve but nowadays most have the spring enclosed in a cage like the one in the photo below.

What Happens? How Do Trumpet Valves Work?

If a valve isn’t pushed down, the air (and standing sound wave) passes through the valve, through the little tube that attaches it to the next valve and so on. In the photo above you can see that the valves are attached to each other by two smaller solid braces and a short tube.

If a valve is pushed down the air comes into it through a different hole which leads to its extra tubing then back through the valve and out to the next valve or to the bell. It seems so simple but there were plenty of attempts to get it right.

Trumpet Valve Maintenance

Other than the occasional major cleaning the valves require only regular oiling to remain functional. The valves in some new Trumpets might require breaking in but that mostly means daily oiling and using the valves a lot – a good recipe for plenty of practising!

If your Trumpet isn’t grimy – and it shouldn’t be – you don’t have to oil the valves by taking them out. You can simply add it from the bottom and work it in. My old Bb Trumpet has been treated that way for over 40 years and the valves are still good. The idea is to keep the valves in their very limited place, keep them free of dust particles and keep them oiled. Use whatever Valve Oil you can find or read this other post. It also helps avoid the problems outlined below.

As a habit, many Trumpet players will loosen and snug up the valve caps from time to time just to make sure they aren’t going to seize up. Both the top and bottom caps should be removable, just not loose. If you hear a strange vibration on your Trumpet they can be the culprits.

Problems with Trumpet Valves

One of the most common problems with Trumpets, especially among beginners, is that it’s suddenly impossible to move air through the Trumpet. Most often that’s the result of a valve (or two, or three) being either in the wrong casing, in the wrong orientation or both.

Most Trumpet valves have the number of the valve stamped right on it. They can be hard to see, but they’re usually there. As for the orientation there is typically a slot in the casing and a brass or plastic tab or guide that fits into that slot. Look in the photo below, you’ll see the little metal tabs. In some older Trumpets the valve guide will go in correctly or exactly backwards.

The valves shown are from a typical student Trumpet. I’ve torn one down (see photo below) so you can see its parts but leave yours in one piece. It’s possible to put it together incorrectly and it’ll either work poorly or not at all. That condition is generally because the plastic (in this case) guide can go into its place in several ways, only one of which is correct. If you’re here because you screwed this up already or the valve just “came apart on its own” pay attention.

Re-Assembling a Trumpet Valve

If you’re forced to reassemble a Trumpet valve the tricky part is getting the guide in correctly. If you’re lucky there is another valve right beside it that isn’t in pieces. Look at that valve and see where the small end of the guide is relative to the number stamp. The guide goes in sideways then flips into its flat position. One side of it is probably flat and the other side likely has a dimple in it that is just a bit bigger than the diameter of the spring. That’s the side the spring rests on. (Tuba player? Skip down)

Put the parts together firmly, oil the valve and gently try it in its place. That means getting the small end of the guide into the groove in the casing. If you’re close and rotate the valve you should hear a satisfying click when it drops into place. At that point the valve shouldn’t want to rotate. Don’t force it or you risk damaging the guider perhaps even the casing. If you can’t blow air through the Trumpet, you’re sure it’s in the slot and you’re sure this valve is the problem then the guide is in backwards. You’ll have to take it apart again and put it in with the small end facing the other way.

If you’re dealing with a situation where all of the valves are in pieces then you’re going to have a lot of trial and error to do. The easiest approach might be to look at another Trumpet if anyone will let you.

Helpful Link: Why won’t my trumpet blow? Checking for and Correcting a Turned Valve

Trumpet Valves Won’t Go Up or Down

Another common issue with Trumpet valves is that one or more simply won’t go down or up. There are two probable causes: first, that the valves are stuck in place from lack of use and/or oil; second, that the casing of the valve has been dented, scratched or bent.

Stuck valves can usually be coaxed out with some valve oil, or even penetrating oil and some gentle persuasion. If you use a penetrating oil plan on bathing the Trumpet when you get that valve moving. If the oil isn’t enough, loosen the top cap and try to spin the valve to ensure that its guide is in the slot. If the Valve is stuck down take off the valve’s bottom cap and see if your finger can push it back up. If not, take out another valve and try using it to push the stuck valve up. Do this carefully so that you don’t double your trouble by damaging that other valve. If this trick won’t work, you need a real repair person.

If the valve is really stuck, or it moves a little, or if it moves well then gets stuck at just one spot STOP. Further attempts are likely to damage the valve, possibly to the costly point of requiring its replacement. There is probably visible damage to the valve’s outer casing and that’s going to require a trained repair person with the right tools. This kind of damage can be frustratingly minor – a tiny little ding can be enough. A bump with a music stand; an aggressive attempt to pull the mouthpiece without the right tool; a ding from a loose mouthpiece inside the Trumpet case – any of these can turn your Trumpet into a Bugle. Get it to a musical instrument repair shop.

A Special Tuba/Baritone Valve Problem

There are some Tubas and Baritones out there that are otherwise good horns and great value but they have one funny little quirk – who knows why. The guides on these Tuba Valves are made so that the depth that the tab extends into the groove is adjustable. That adjustment is set at the factory so that the valve goes up and down well and stays in its place. Unfortunately the adjustment is made by loosening the valve stem – a favourite activity of bored student Tuba players.

The result is often that the valve guide comes loose, backs off and the valve is free to rotate in its casing. A clever kid might figure this out and spin away, each spin removing a bit of that plastic until there isn’t enough left to do the job regardless of who attempts to fix it. You need a new guide. I used to carry a couple of spare Tuba valve guides in my repair kit when that was a part of my reality. If you’re lucky and the guide has enough meat on it to stay in the groove then just reassemble it, take your best guess on the depth and try it. Your goal is to get back to the state in which it goes up and down freely but won’t rotate. If you’re reading this in a panic before an event get it lined up, mark it with tape and explain it to your Tuba player. Another great reason not to fiddle with the valves.

Another part of this design is that the guide has a little nub on its underside that fits into a small hole in the top of the valve. The funny part is that there is also a (generally larger) vent hole in the top of the valve and the nub can wander into that hole if it has been loosened. The result of that condition can be that the instrument is playable but sounds bad (because the valve’s ports aren’t lining up with the instrument’s tubing). This can also happen if you’ve been through the whole business above but got the nub into the wrong place. Aren’t valves great?

This guy says most of that in a video.

Rotary Valves on Trumpets

Rotary valves do the same thing as piston valves but have their own set of issues that are best dealt with another time – sorry if that’s you.

Do I Need a Valve Guard for My Trumpet?

No, you don’t need a valve guard for your trumpet. Lots of people have them, but the only good reason I can think of is that it feels good in their hand. I suppose it could reduce wear on the finish but I can’t see that wear ever mattering. It is possible that such a guard could prevent potential dents in the valves as outlined above. Valve guards are also called valve covers.

A Few Piston-Valved Outliers – just for fun

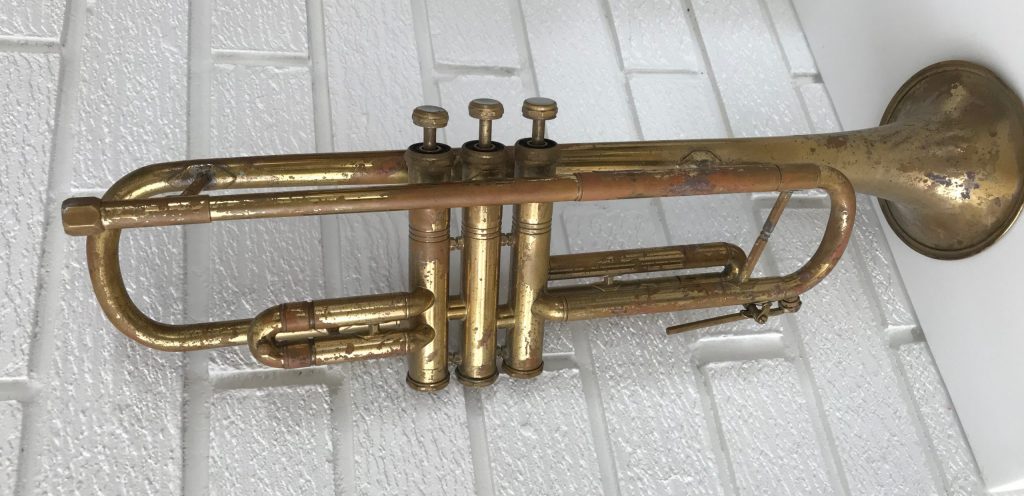

Ok. I have to tell you about that old beater. It was on the “as is” shelf in a Salvation Army Thrift store in the early 80’s. It was a bunch of Trumpet pieces in a plywood box but the thing I liked about it was the absence of a second valve slide. The clever folks at the Wohlrab plant figured out how to use the space inside the valve to add the right length to lower the pitch by a semitone. It’s a bit funky but it does actually change the pitch. Unfortunately it also changes the tone quality from bad to worse. This was clearly a budget horn when it was playable.